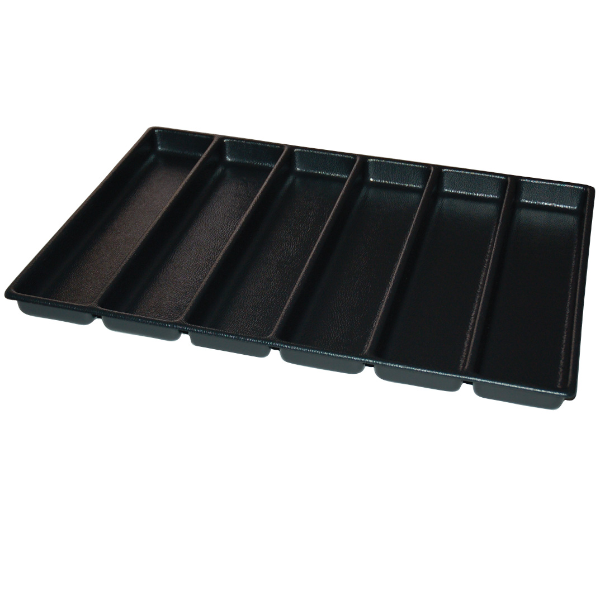

Technical Specifications Item Machinists Tool. Please contact us if you have any questions. The main image is typically a stock photo. Photos in the slideshow reflect actual photos of the items. All of the cabinets drawers still open and close and the cabinet still locks and unlocks just fine. The front door does not close properly, and the top lid needs extra effort to close all the way. The cabinet itself is scratched and dented in several palces including its top. The original packaging for this item is damaged. It features brown coloring, wrinkle finish, and 6 drawer dividers, and folding chrome handles. Has 11 drawers, and a 75 pound drawer capacity. 11 Drawers, Machinists Tool Cabinet This is a Kennedy machinists tool cabinet. Some shops used to have 20+ moderately skilled guys running things and now that same company works on 1 or 2 highly skilled guys doing the same or more work but with CNC to help.Kennedy 3611B Felt Lined. There are manufacturing shops that the boss doesn't have a clue what's going on and relies on the Machinist/Operator to make the magic happen, and there are shops that are so deep in process and paperwork that the machinist needs to check out certified safety glasses and be in uniform, and wouldn't dream of bring his own tools in the shop. Nowadays with so much global manufacturing, everyone's definition's of what makes a machine shop have become muddled. This is also considering that "back then" every industrial zone and sector had machine shops and machinists in work force circulation and there were more common habits and practices uniting them. The guy running the turret lathe 70 years ago had a small tool box, while the guy pushing the CNC button today might have a favorite pair of digital calipers. While they're still around, there's also less hand tools in play in production shops.

When you move on to another job, it's easier to grab a little machinist chest than to call your buddy with a truck to move your massive rolling Kennedy monolith. The same philosophy drives most tradesmen that buy their own tools today, but "back then" when these practices were more common it wasn't prudent to invest in a bunch of tools that you wouldn't use on a daily basis and then had to transport and store between jobs. You could use the shop drift that's been beat to heck and never gets put away, or get your own and always know where it is. Depending where you work, they likely have tools available for you, but why would you use the ratty micrometer that's been kicked around the shop forever, when you can buy your own that had the style of spindle you like the most.

The small tool chests work along the principle that the company supplies everything to do the job, but tools that are used daily and are a little more touch sensitive are left to the employee (squares, calibers, micrometers, etc.). It also depends which class of work is being done then and now (tool-n-die, or production, or repair.) AS JST noted, the divide between the companies resources and your own resources has likely shifted, but IMO it's less of a question of what specific tools are owned by who, and more about the needs and principle of it.

0 kommentar(er)

0 kommentar(er)